Dissolving

Cellulose fibers are produced by transforming raw materials through a series of steps into a viscous, uniform and degassed spinning solution.

Cellulose fibers are produced by transforming raw materials through a series of steps into a viscous, uniform and degassed spinning solution.For any fibers that require a dissolution step, the kneading reactor technology can produce high-quality spinning dope . thereby enabling the manufacture of high-quality fibers with maximum output and minimum cost.

The unique process characteristics of the kneading reactor include intense mixing and kneading, continuous surface renewal, and variable residence time.

Lyocell fibers

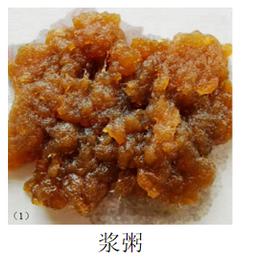

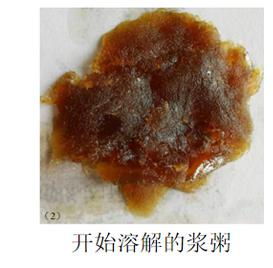

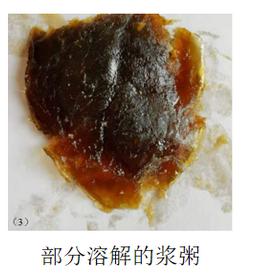

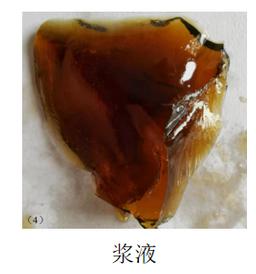

Cellulose and additives continuously dissolve in the kneading reactor, which provides functions such as heat treatment, evaporation, degassing, and strong stirring.The final product is a transparent light yellow spinning solution, which is very uniform and free of bubbles and dissolved gases.

Depending on the process, the solvents may be:

■ N-methylmorpholino-N-oxide (NMMNO)

■ Various ionic liquids

■ Acids

■ Caustic alkali

Aramid Fibers

Aramid fibers are typically wet-spun from a viscous solution of poly(p-phenylene terephthalamide) and (PPTA) polymer in concentrated sulfuric acid.The thermal energy released during the exothermic dissolution process aids in the melting and dissolution of the polymer.The polymer solution is viscous and non-Newtonian. The requirement is to create a homogeneous, degassed solution with a controllable high polymer concentration.

We will be glad to help you! Please contact us

Company address:

501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address:

No. 18, Fuxing Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Telephone: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn / sales@lykzhb.cn

Company address:

501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address:

No. 18, Fuxing Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Telephone: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn / sales@lykzhb.cn

Copyright © 2025 Luoyang Kaizheng environmental protection processing equipment Co., LTD