News

Core Gear: Tackle Solid Waste/High-Viscosity, Boost Industrial Green Shift

Background: Solid Waste Demand Up, Tech Innovation as Core Solution

In 2025, with the deepened "dual carbon" policy and upgraded environmental standards, resource utilization of industrial solid waste and harmless treatment of high-viscosity materials have become industry focuses. Per the 2024 White Paper on the Renewable Resources Industry, 32% of SMEs see over 15% raw material loss due to poor sorting accuracy of solid waste equipment, driving urgent demand for high-efficiency, eco-friendly equipment². Against this backdrop, Luoyang Kaizheng Environmental Protection Technology & Equipment Co., Ltd. (hereinafter "Luoyang Kaizheng") offers customized industrial clean production solutions via its three core business segments.

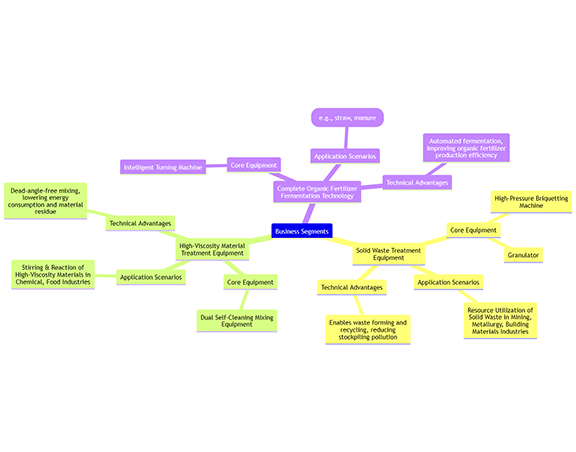

Three Core Product Matrix of Kaizheng Environmental Protection

Three Core Product Matrix of Kaizheng Environmental Protection1. Solid Waste Treatment Equipment

▶Core Equipment: High-Pressure Briquetting Machine, Granulator

▶Application Scenarios: Resource Utilization of Solid Waste in Mining, Metallurgy, and Building Materials Industries

▶Technical Advantages: Enables waste forming and recycling, reducing stockpiling pollution

2. High-Viscosity Material Treatment Equipment

▶Core Equipment: Dual Self-Cleaning Mixing Equipment

▶Application Scenarios: Stirring & Reaction of High-Viscosity Materials in Chemical and Food Industries

▶Technical Advantages: Dead-angle-free mixing, lowering energy consumption and material residue

3. Complete Organic Fertilizer Fermentation Technology

▶Core Equipment: Intelligent Turning Machine

▶Application Scenarios: Resource Utilization of Agricultural Wastes (e.g., straw, manure)

▶Technical Advantages: Automated fermentation, improving organic fertilizer production efficiency

Technical Highlights: Kaizheng’s Eco-Equipment (High Efficiency + Intelligence)

The equipment design of Luoyang Kaizheng closely aligns with the current trends in environmental protection technology:

Solid Waste Treatment Equipment: Adopts an integrated "crushing-sorting-molding" process, suitable for processing particles with a particle size of less than 50mm. It synergizes with the high suction efficiency (99%) of vacuum suction trucks, covering the entire chain from solid waste collection to resource utilization ¹.

High-Viscosity Material Equipment: Features an original self-cleaning mixing system, which solves the problems of wall adhesion and residue in traditional equipment caused by material viscosity. Its energy consumption is 20% lower than the industry average.

Intelligent Turning Machine: Equipped with IoT sensors, it monitors fermentation temperature and humidity in real time, and enables remote adjustment of turning frequency, contributing to the green circular economy in agriculture.

Application Cases: From Laboratory to Production

LineIn a project for a steel plant in Henan, the high-pressure briquetting machine provided by Luoyang Kaizheng presses steelmaking dust into pellets for reuse. This reduces annual solid waste discharge by 12,000 tons and creates over 8 million yuan in new economic benefits. Similar cases have covered more than 10 provinces across China, involving industries prone to dust pollution such as cement, coal, and non-ferrous metals.

We will be glad to help you! Please contact us

Company address:

501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address:

No. 18, Fuxing Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Telephone: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn / sales@lykzhb.cn

Company address:

501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address:

No. 18, Fuxing Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Telephone: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn / sales@lykzhb.cn

Copyright © 2025 Luoyang Kaizheng environmental protection processing equipment Co., LTD